Amada Ap100 Software

Additional forearm protectors were issued to frontline troops. Light combat armor fallout 4. The individual components included a combat helmet issued with matching goggles in hazardous environs, front and back ballistic plates, and a pair of axillary protectors. The lower body was protected by a pair of thigh plates, worn together with a groin and kidney protector.

Purpose: Win-NEST Auto Nesting (LASER) Education Drawing No.: JN-LAS-01 to JN-LAS-16 Points: Starting Auto Nesting Plan Information Selecting a Workshe. AP100US v2013.05 Update (Release date: May 9, 2014) AP100US v2013 can download and automatically install patch updates by selecting 'Online Update' from the AP100US program interface Help Menu. TUBE Solution Pack: software solution for laser profiling machines The pack comprises the following applications: AP100 EU PRODUCTION DESIGNER SHEETWORKS VPSS 3i BLANK Dr ABE Tube. The production flow initially involves assigning sheet metal attributes to 2D and 3D drawings and saving them in a database using SheetWorks.

The various options make SheetWorks a flexible tool. For instance, sheet metal sequences can be batch processed and automatically saved on the AMADA AP100 SSD server. The Unfold-Manager can fully automatically analyze, process, convert and save an unlimited number of 3D models (STEP, IGES, SWG). Specifically developed for sheet metal industry,the AP 100 software includes an integrated 2D/3D CAD-CAM solution,100% AMADA's developement. Below is a list of few features of the software » Auto/Manual Tool/Cutting assign and sequencing » Can program Punch, Laser and Comb machines » Single part, Nested or Multi-part sheet layouts.

VPSS 3i

Sheetmetal Engineering System VPSS3i is the factory -reform solution to make your factory into a smart factory.

Main applications Composing VPSS3i

Amada Integrated Network Solution

Sheetworks for Unfold

3D Data Import and Unfold

» SheetWorks for Unfold can import 3D Data from many Design software available in the market.

» Imported data can be unfolded accurately as per Amada Bending Attributes and tooling available.

Software Screenshots (Click on the images for larger view)

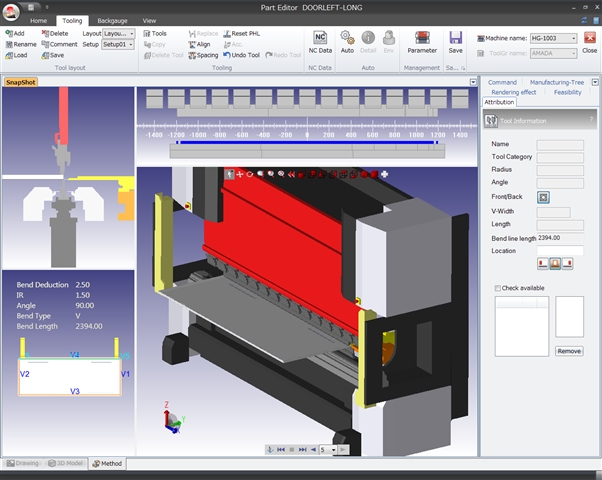

SDr. ABE Bend

Increase your Press brake productivity by cutting down setup time. Dr.ABE Bend automatically decides tooling selection, bend sequence, D/L value, Position of tooling to process the part without manual intervention.

Integrated with AP100

» Auto tooling section and sequences by Dr. Abe

» Complete manual bend sequence

» Feasibility checking

» 3D viewing of bend process

AP100

Specifically developed for sheet metal industry,the AP 100 software includes an integrated 2D/3D CAD-CAM solution,100% AMADA's developement. Below is a list of few features of the software

- » Auto/Manual Tool/Cutting assign and sequencing

- » Can program Punch, Laser and Comb machines

- » Single part, Nested or Multi-part sheet layouts

- » Over-travel and Clamp Dead Zone error messages

- » Multiple Turret configurations can be saved

- » Program simulation & Error checking

- » Automatic or Manual repositioning

- » Import/Export DXF, IGES or DWG files

- » Automatically dodge clamps with sequence

- » Tool path optimisation

- » Visual numbering of Cam sequence

- » Bend Deduction Management

Software Screenshots (Click on the images for larger view)

Dr.ABE Blank

Dr.ABE Blank is the most advanced blanking solution available for programming Amada machine. Dr.ABE_Blank makes user modification of parts and nesting simple, including the most demanded features in the industry. Years of innovation are seamlessly integrated with our AICAM engine to create our Expert AI CAD/CAM system, complete with scheduling, nesting, and every function needed to bring your shop to the next generation in automation.

Merits :

- 1. Shortening operation of program making time

- 2. Shortening of processing time

- 3. Reduction in the cost of materials

Peu / Win

An add-in module that operates with SolidWorks™ to process sheet metal

Hp Mediasmart Download

- » SheetWorks Disassembly: A single sheetmetal solid model can be disassembled into two or more sheet metal parts

- » SheetWorks allows forming and special tools to be assigned to a sheetmetal part in 3D CAD

- » SheetWorks has the ability to output unfold drawings as a BMF file with associated bending and tooling data to be used by Amada NT machines

- » SheetWorks can import a wide variety of 3D and 2D CAD files including IGES, Parasolid, STEP, ACIS (.sat), Pro/E (.prt, .asm), DXF and DWG files

- » SheetWorks can include assembly features for OEM designers

Amada Ap100 Software Tutorial Pdf

vFactory

A realistic working model of the factory along with working status of Individual machine, product information being Manufactured is shown. It displays the result information in real time using Virtual image of the factory.